Microfiber describes any synthetic fibers that weigh less than one denier and are thirty times finer than cotton, ten times finer than silk, 1/16th of the thickness of human hair and almost invisible to the naked eye. Although there are many different types of microfibers (e.g. nylon, kevlar, polyester, and polyamides}, conventional microfiber refers to a fabric composed of polyester and polyamide.

In the late 1950s, scientists began experimenting with ultra-fine fibers in order to take advantage of manufacturing methods: utilizing continuous filament fibers. Microfiber in apparel applications led the way in the late 1970s and continued expanding until the 1990s: when the textile industry saw the widespread acceptance of microfiber as a revolutionary cleaning product.

Production Process

The conventional term microfiber describes a fabric produced with polyester and polyamide at the most common ratio of 80:20 respectively, although different synthetics can be added at varying ratios to yield the fabric trails desired. Polyester is lyophilic; it attracts dirt and oils. Polyamide is hydrophilic, which means it absorbs water.

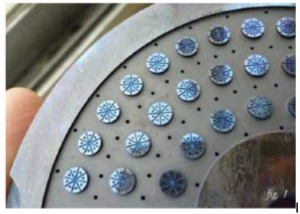

The process of producing microfiber fabrics begins by melting down polyester and polyamide pellets in separate vats. At this stage the liquid polyester and polyamide vats are pushed or extruded simultaneously through jet moldings that contain seventy-two pie-shaped segments. Each pie shape contains eight segments of polyester and eight segments of polyamide with trace amounts of oil separating the two polymers so they do not mix. (See figure 1.) The seventy-two pie shapes combine to create one filament.

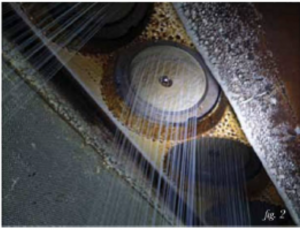

During the extrusion process, air moves through the molding plates to cool the liquid polymers into fibers. Gravity allows the fibers or microfiber yarn to form in continuous filaments. (See figure 2.) Once the fibers are collected, they can be woven or knitted into fabric.

The next step, and one of the most crucial in the process, involves submerging the woven or knitted fabric in a dye or bleach bath with an alkaline solution. This is also known as the splitting process, in which the polyester is corroded by a controlled chemical process that splits the microfibers to create cavernous openings in the fiber. ln the end, the split microfiber contains more than 200 million openings per square inch of fabric (16 split segments per pie shape, 72 pie shape per filament, and 200,000 filaments per square inch of fabric). Whereas unsplit microfibers perform in the same way as normal synthetic yarns, split microfibers give the fabric enhanced absorbing and dirt-trapping capabilities. The final stage of microfiber production, cutting and sewing, is the same as that of products made with more traditional yarns and manufacturing methods.

Features

Microfiber products have characteristics and properties (e.g. greater absorbency, durability, and efficiency) that make them more desirable than conventional cotton products. Many of these attractive features derive from the greater surface area of the fabric, which results from the splitting process. Microfiber fabrics can have as many as 200,000 fibers per square inch and thus 40 times more cloth surface, making it possible 10 clean dust, grease, water, or oils with a single pass or swipe of the microfiber towel. Technically, microfiber is not absorbent because the fibers do not absorb water in the same way that cotton fibers do. Instead, they merely trap water into conduits in the thousands of fibers. Microfiber soaks liquids by means of the capillary effect, a phenomenon in which liquid flows in the opposite direction of gravity through channels in the fabric. The thousands of fibers surround and lock the water molecules, thus preventing them from escaping. This gives microfibers the ability to hold up to eight times their weight in water. Further, since the microfibers do not absorb water, they then can dry much more easily, because water is simply pushed out of the caverns where it is held rather than having to dry in the usual way after it has been absorbed by saturated fibers. In addition, the synthetic fibers are categorically plastics and thus arc woven so tightly with so many fibers in each inch that they possess greater durability.

Best Practices

As is the case while washing any textile material, careful attention is required when determining the appropriate washing and drying temperatures, cycles, and chemicals for microfiber products. Microfiber fabrics should be machine washed in warm water not to exceed 160° Fahrenheit. Microfibers should never be washed with terry items, because the lint from the cotton fibers cling to the fabric and are difficult to remove, clog the microfiber caverns, and thus reduce the fabric’s effectiveness. Detergent should not exceed a pH level of 11 since alkaline solutions will eat away at the composition of the microfiber. Testing has shown that bleach may be used in order to achieve optical whiteness and can be well tolerated by the product. However, bleach is not recommended in concentrations above 12%, or for colored microfiber product. Most importantly, eliminate all fabric softeners, as they will act as a wax and seal the porous caverns, thereby disabling the ability of the microfiber to trap dust, water, and greases. Washing microfibers in conjunction with high acids or bases will damage and break down the polyester and polyamides and thus render the microfibers ineffective.

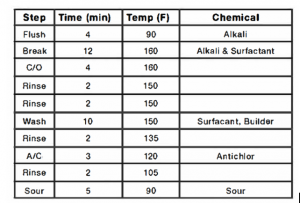

Microfiber towels usually weigh less than comparable cotton towels. Tests conducted by Ecolab1, an independent laboratory, in a 35 pound capacity Milnor washer/extractor indicated that for best results Microtex® bar mops should be loaded at approximately a 75% load factor when compared to traditional cotton bar mops. The tests yielded a standard wash formula for a 35 pound Milnor washer/extractor. The chemical usage and wash cycles are listed below in Table 1.

Drying temperatures should remain below 140° Fahrenheit. Do not load microfiber fabrics into a dryer that is already hot. Remove the microfiber promptly after a drying cycle so the fabrics do not sit for long periods on a hot metal drum. Excessive heat during drying can cause the microfiber material to shrink and even melt if the temperature is too high.

The ideal way to dry a microfiber fabric or cloth is to squeeze the water from the cloth and tumble dry the excess water out. Not only does this method use less energy and thus cost less, it isn’t harmful to the microfiber and thereby lengthens its life cycle. It is important to remember that because microfiber is such an effective cleaner, it is not necessary to pretreat spills and stains on surfaces excessively with chemicals while cleaning. Instead, by letting the microfiber do the work, end-users may use smaller amounts of chemicals or find they can be used less frequently.

ROI

Since microfiber towels weigh less and take up less volume than cotton towels, 33% more microfiber towels can be added to a wash load. This equates to 33% fewer wash loads and thus a 33% reduction in energy costs, water, chemicals, setup and change over time. Furthermore, microfiber towels require substantially less time and energy to dry and can even be air dried effectively if water is first pressed out of the towels. Depending on the type of dryer used and it temperature level, drying cycle times can be reduced by 40-60% from those used to dry cotton bar mops. Microfiber processing costs are substantially lower than those of conventional cotton products. Furthermore, if processed correctly a microfiber towel can yield up to 200 washes.

The features and benefits of microfiber products have contributed to exponential growth in the retail sector with widespread acceptance amongst consumers. Research and Development teams continue to improve microfiber fabric appearance, feel, and function by altering bi-component fiber content ratios and finishing processes in order to develop appropriate solutions for specific applications in additional markets.